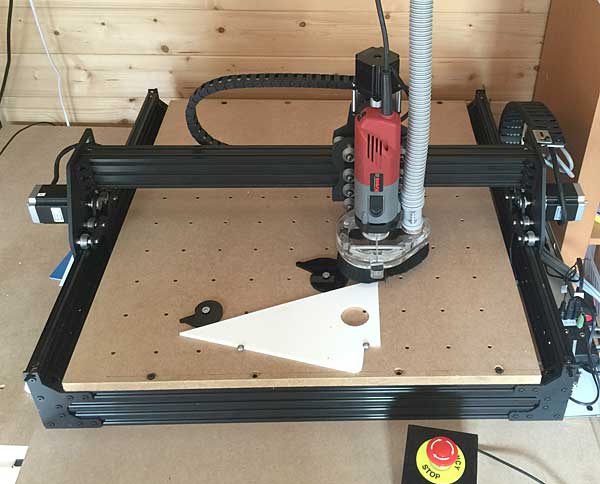

Openbuild OX CNC from ooznest.co.uk frame kit 750×750 size

Putting it together was like getting my Lego Techic Car 853 back in 1977, (best ever Christmas present).

All the parts I needed and a very clear instruction manual, kind of unique for me.

That was the easy and quick part.

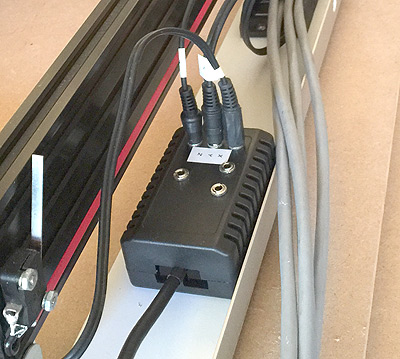

I bought a 24v power supply and one Stepper at the same time as had others left over.

The Controller was a cheap eBay purchase with individual stepper drivers. These were configured, wired up and fitted into a 1U server case.

Other parts to finish were, Cable Drag Chain, 4 Core CY Flex Cable, Aviation connectors, Stop Button, micro switches, Kress Milling Motor.

I really like Mach3 and so bought the full version of this CNC Software.

I made a break out box for the limit and other switches back to a 9pin connector and lead, this gives a bit more flexibility for later upgrades like probes. Everyone likes probes.

Stop Box was laser cut and plugs into the break-out above.

The bed is MDF, 6mm hole through, 8mm counter sunk and 12mm routed to fit the T-nuts, 80 of these should be enough.

Hold downs I made from acrylic, snail spirals in a few sizes. They can hold any shape and are such a low profile don’t get in the way, you can even double them up for weird size material.

Most of the time was spent making a new Kress motor mount with vacuum attachment. Hell it makes a mess without one.

This I wanted to be of transparent acrylic. It snaps together with hard drive magnets I embedded, this also worked for the draft excluder I bent into shape as this also snapped on nicely and wouldn’t hurt if got caught on a component as it’s not physically attached.

The Video explains it better.

Working and not making a mess!!

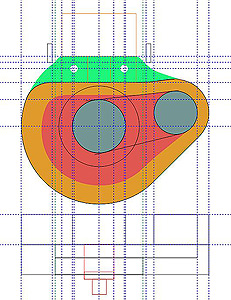

So what can it do? Well stuff like this:

V-carving

And a load of other stuff I’ve not done yet.